A Fly’s Eye Lens Array is a 2-D array of lenses including individual optical lenslets assembled or formed into a single optical element. It is used to spatially transform light from a non-uniform distribution to a uniform irradiance distribution at a defined illumination plane.

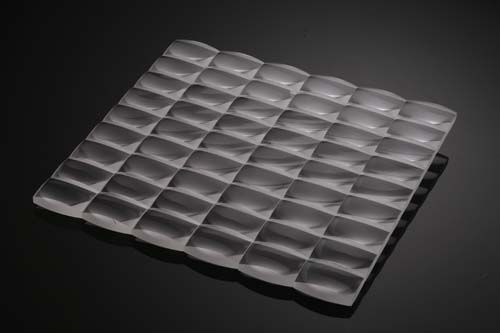

A Fly’s Eye Lens Array

As the name suggests, a Fly’s Eye Lens Array is directly inspired by nature itself.

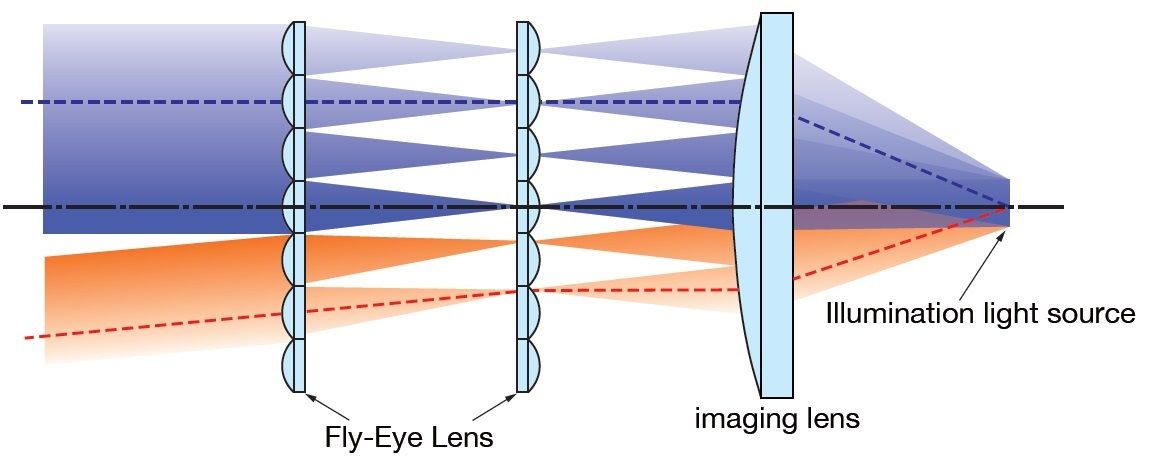

The array is formed by a series of small lens combinations, which are either linear or diagonally arranged. Fly’s eye lens arrays are mostly used in pairs to spatially homogenize or make a light source uniform at the illumination plane.

The two arrays are called the ‘objective array’ and the ‘field array’ and are used with a so-called ‘condenser lens’. The objective array images the source at the field array. The field array reimages all of the fields with the condenser lens so they overlap at the illumination plane and create a uniform irradiance.

Fly’s Eye Lens Array Applications

A Fly eye lens array has a broad scope of applications in micro display and projection applications. Using a fly’s eye lens array is almost always used with lamp assemblies with a parabolic reflector providing semi-collimated light. Presently, they are mostly used in LCD digital projector light engines in the illumination section to deliver spatially uniform or homogenized illumination to the spatial light modulator illumination plane.

Main parameters of the microlens array:

1. The size and material of the microlens

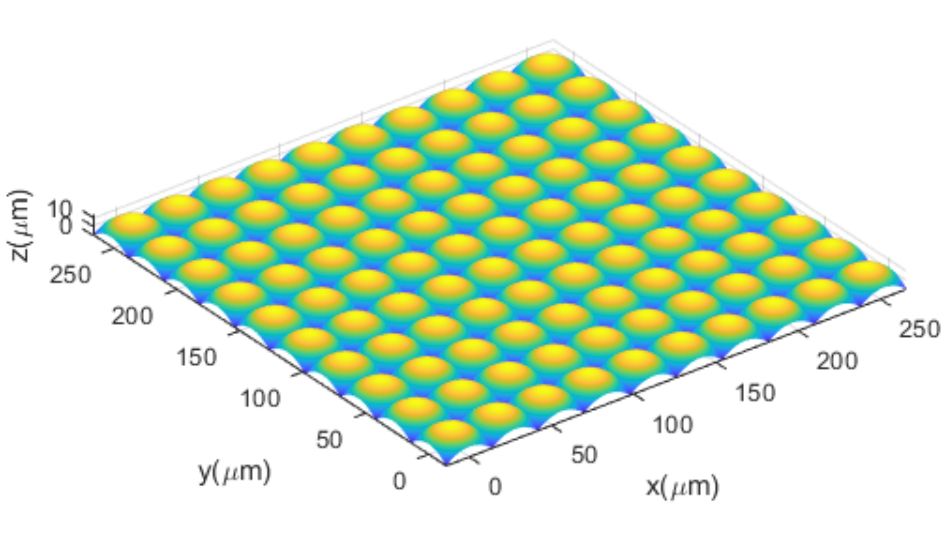

2. The shape of the microlens, cylindrical lens, spherical mirror, aspheric lens, non-cylindrical lens, astigmatic lens

3. Arrangement of microlenses: square array square lens, square array round lens, hexagonal arrangement, random arrangement, etc.

4. Microlens cycle (subunit diameter), focal length, etch depth (height), radius of curvature

5. Surface shape: For diffractive elements, there are generally two types of continuous surface type and discontinuous surface shape (step type). The continuous surface type can eliminate chromatic aberration and is suitable for applications such as wide-band system imaging and spiral phase plate.

For the above parameters, we can provide customization.

Micro lens array processing capability, customization ability

Years of precipitation, we have accumulated a wealth of experience in the mask, etching, micro-optical surface technology, through the standard design, processing flow, usually only one month to allow users to achieve satisfactory results customized product.

1. The range of the microlens covers the range of 190nm~10600nm, matching the wavelengths of various common lasers.

2. It can process not only stepped microlenses of 2~32 steps, but also various continuous surface type microlenses. At present, the processes of 2 steps, 4 steps, 8 steps, 16 steps and 32 steps are very mature, and the diffraction efficiency can be 95%. For continuous surface structure, we can achieve numerical aperture: 0.01~0.5, surface error: <2%.

3. The material of the microlens is generally selected from materials such as glass, quartz, tantalum, zinc selenide (ZnSe), silicon, K9.

Post time: Jun-30-2022